Thermal Solution for silicon verification

Thermal Solutions for silicon verification

Advanced Thermal Forcing Cooling Solution

Sysmetric Thermal Forcing Systems delivers advanced thermal solutions for silicon test labs, ensuring exceptional performance. Our products are renowned for their high coefficient of performance, durability, and competitive pricing. We specialize in custom designs tailored to meet specific cooling power and size requirements.

Sysmetric Thermal Solution

FAQ

Thermal Forcing

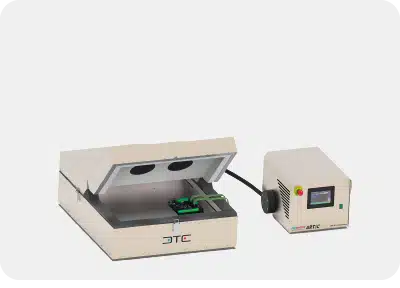

Liquid or Air cooling is commonly used to cool CPUs as well as other computer components. It usually consists of a CPU liquid block, a liquid pump, and a heat exchanger (mostly a radiator and fan). Advantage is low cost. Liquid cooling allows quieter operation (potentially fan less), or improved processor speeds.

Phase Change Cooling

Phase change cooling technology (vapor compression) is suitable when a very low temperature is desired, efficiency is much higher and does not need cooling liquid to remove the heat. Disadvantage of phase change technology is higher cost for initial system purchase but it is very energy efficient – for long term usage.

Peltier Technology

Thermal Electrical Cooler (TEC-Known also as Peltier cooling). Advantage is low cost, disadvantage is that it can’t always remove the amount of heat capacity needed at very low temperatures and it’s efficiency is very low (~30%) .

Thermal solutions for Silicon verification

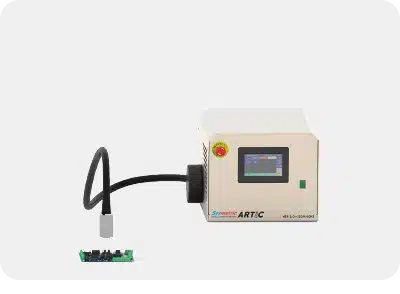

The demand for high-performance microprocessors has resulted an escalation of power dissipation and heat flux at the silicon level. High Si temperature cause various problems such as increased leakage, accelerating failure mechanisms and influence timing failures.

Silicon Verification

The tests have to be conducted to get necessary data to show any gaps from the spec provided by the vendor and the actual product. The desire for small form- factor chassis, new car industry specification demand for very low and very high Silicon operating temperatures bring the thermal solution challenge to new levels. Silicon validation platform are built to validate Processors, Chipset and PCB’s to ensure quality and reliable products in temperature range of -40c to 125c .

Thermal Validation

These validation phase is crucial step in releasing the product to market. Recently it become challenging to design a forcing thermal solution for high speed processors, Networks components, Graphic cards, Memory voltage regulators, etc. Thermal-related effects are considered as a major roadblock in the design on next generation microprocessors.