Phase change cooling system is for Effective thermal management it is crucial in electronic systems design to ensure reliability, performance, and longevity. One innovative approach that has garnered attention is phase change cooling. This technique leverages the latent heat properties of materials to regulate temperature fluctuations, offering a passive yet efficient solution for heat dissipation.

Understanding Phase Change Cooling

Phase change cooling involves utilizing materials known as phase change materials (PCMs) that absorb and release thermal energy during their transition between solid and liquid states. When electronic components generate heat, PCMs absorb this heat as they melt, effectively reducing temperature spikes. Upon cooling, these materials solidify, releasing the stored heat. This cyclical process helps maintain optimal operating temperatures within electronic systems.

Integration of Phase Change Heat Exchangers

Incorporating phase change heat exchangers into electronic systems enhances thermal regulation. These devices utilize PCMs to absorb excess heat during peak loads and release it during cooler periods, thereby stabilizing temperature variations. The design of these heat exchangers often includes features like metal foams to improve thermal conductivity and structural integrity.

Phase change colling system Silicone-Based Thermal Mitigation Solutions

Silicone materials play a pivotal role in thermal management strategies. Silicone thermal mitigation solutions, such as thermally conductive silicone gels and encapsulants, offer excellent heat dissipation properties. These materials provide electrical insulation and mechanical flexibility, making them ideal for protecting sensitive electronic components from thermal and mechanical stresses.

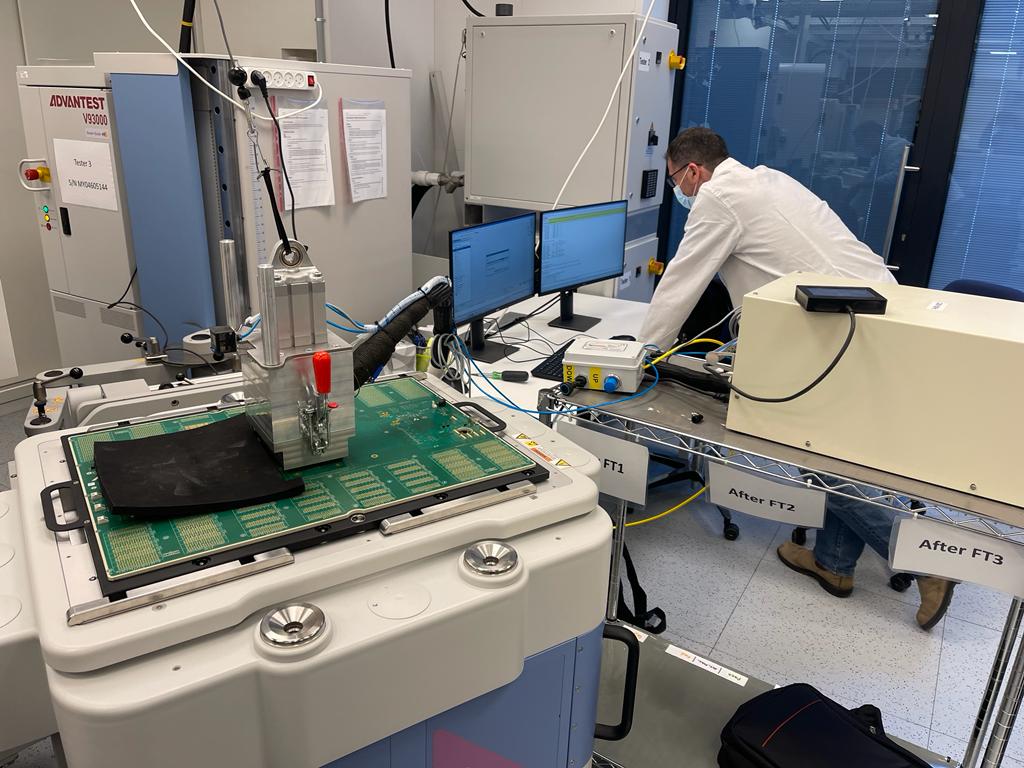

Importance of Temperature Validation Systems

Implementing a robust temperature validation system is essential to ensure the efficacy of thermal management solutions. These systems monitor and record temperature data, enabling engineers to assess and optimize thermal performance. Accurate temperature validation helps in identifying potential issues and verifying that cooling strategies meet design specifications.

Temperature Testing in Electronic Systems

Conducting comprehensive temperature testing is critical in evaluating the thermal resilience of electronic systems. This process involves subjecting devices to various thermal conditions to observe performance and identify potential failure points. Temperature testing ensures that electronic components can withstand real-world operating environments without compromising functionality.

Conclusion

From an engineering standpoint, integrating phase change cooling techniques, such as phase change heat exchangers and silicone-based thermal mitigation materials, offers a promising avenue for enhancing thermal management in electronic systems. Coupled with rigorous temperature validation systems and testing protocols, these strategies contribute to the development of reliable and efficient electronic devices capable of operating under varying thermal conditions.

In the automotive industry, the relentless advancement of electronic systems has led to increased power densities and thermal loads on integrated circuits (ICs). Ensuring the reliability and performance of these ICs under varying thermal conditions is paramount. Solid–solid phase change cooling has emerged as a promising passive thermal management solution, necessitating rigorous testing of chips to validate its efficacy.

Understanding Solid–Solid Phase Change Cooling

Unlike traditional solid–liquid phase change materials (PCMs) that transition between solid and liquid states, solid–solid PCMs undergo a crystalline structure transformation while remaining in the solid phase. This transition allows them to absorb and release latent heat without the risks associated with liquid phases, such as leakage or encapsulation challenges. Materials like vanadium dioxide (VO₂) have been studied for their potential in temperature regulation through solid–solid phase transitions .

Importance of Chip Testing in Automotive Applications

In automotive environments, electronic components are subjected to a wide range of temperatures, vibrations, and mechanical stresses. Implementing solid–solid phase change cooling requires comprehensive testing to ensure that chips can withstand these conditions while maintaining optimal performance.

Temperature Cycling

This process exposes chips to repeated cycles of extreme temperatures, simulating the thermal variations encountered in automotive settings. It helps identify potential failures due to thermal expansion and contraction.

Thermal Shock Testing

Chips are subjected to rapid temperature changes to assess their resilience against sudden thermal gradients. This is crucial for detecting vulnerabilities in solder joints and material interfaces .

Accelerated Aging

By simulating prolonged operational periods in a condensed timeframe, accelerated aging tests predict the long-term reliability of chips under continuous thermal stress.

Advantages of Solid–Solid Phase Change Cooling in Automotive Electronics

- Enhanced Reliability: Maintains consistent operating temperatures, reducing thermal-induced failures.

- Passive Operation: Eliminates the need for active cooling components, leading to simplified system designs and reduced energy consumption.

- Leakage Prevention: Since the material remains solid throughout the phase change, risks associated with liquid leakage are mitigated.

Conclusion

The integration of solid–solid phase change cooling in automotive electronics offers a robust solution to thermal management challenges. However, its successful implementation hinges on meticulous chip testing to ensure durability and performance under the demanding conditions of automotive applications. As vehicles continue to evolve into more sophisticated electronic systems, such innovative cooling strategies will be instrumental in driving reliability and efficiency.