In the rapidly evolving world of semiconductor design, thermal management has become a critical factor in ensuring the performance, reliability, and longevity of silicon chips. As these components become more powerful and compact, managing heat dissipation and thermal stress is paramount. This is where Silicon Thermal Verification plays a vital role. In this guide, we’ll delve into the intricacies of silicon thermal verification, explore the technologies used in the process, and highlight why it is essential for modern electronic systems.

What is Silicon Thermal Verification?

Silicon thermal verification is the process of testing and validating the thermal characteristics of silicon-based semiconductor devices. This verification ensures that the chips operate within safe temperature ranges, preventing thermal-induced failures, and ensuring optimal performance under various operating conditions.

Thermal verification typically involves subjecting the silicon chip to controlled temperature variations and monitoring its behavior. By doing so, engineers can identify potential hotspots, assess cooling efficiency, and validate the chip’s ability to maintain thermal stability during operation.

Importance of Thermal Verification in Semiconductor Design

The significance of thermal verification cannot be overstated in the semiconductor industry. As electronic devices continue to shrink in size while increasing in complexity, thermal management becomes increasingly challenging. Thermal Management Solutions are crucial for the following reasons:

- Prevention of Overheating: Overheating can cause immediate damage to silicon chips and lead to long-term reliability issues. By verifying thermal performance, engineers can design systems that prevent overheating, ensuring the longevity of the device.

- Optimized Performance: Temperature variations can affect the electrical characteristics of semiconductor devices, leading to performance degradation. Thermal verification ensures that the chip operates efficiently across its intended temperature range.

- Compliance with Industry Standards: Many industries have strict thermal performance standards for electronic components. Thermal verification helps ensure that silicon chips meet these standards, which is critical for regulatory compliance and market acceptance.

Key Technologies in Silicon Thermal Verification

To conduct effective silicon thermal verification, several advanced technologies are employed. These include:

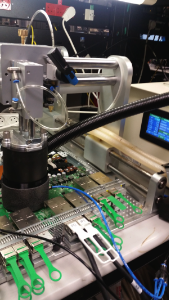

- Thermal Forcing System

- A Thermal Forcing System is used to apply precise temperature control to silicon chips during testing. These systems can rapidly cycle between hot and cold temperatures, simulating real-world operating conditions and identifying potential thermal issues before the chip is deployed.

- Thermal Forcing Cooling Solution

- As part of the thermal verification process, a Thermal Forcing Cooling Solution is often integrated to manage the heat generated during testing. This ensures that the device under test (DUT) is maintained within its safe operating temperature range.

- Temperature Control Systems

- Temperature Control Systems play a crucial role in maintaining consistent thermal conditions during the verification process. These systems ensure that the silicon chip is exposed to the correct temperatures for accurate testing and validation.

- Precision Cooling for Silicon Chips

- Precision cooling is essential for maintaining the integrity of silicon chips during thermal verification. Precision Cooling for Silicon Chips involves the use of advanced cooling technologies that can accurately control temperature fluctuations, ensuring that the chips remain within their specified thermal limits.

- Advanced Thermal Testing

- Advanced Thermal Testing techniques are employed to assess the thermal behavior of silicon chips under various conditions. These tests can include thermal cycling, thermal shock testing, and other methods that simulate the stresses a chip might encounter during its operational life.

Best Practices for Effective Silicon Thermal Verification

Achieving reliable results from silicon thermal verification requires adherence to several best practices:

- Accurate Thermal Modeling: Before physical testing, engineers should create detailed thermal models of the silicon chip. This allows for the identification of potential hotspots and helps in designing effective cooling solutions.

- Comprehensive Testing Scenarios: Thermal verification should cover a range of operating conditions, including extreme temperatures, to ensure that the chip performs reliably in all expected environments.

- Integration with Design Process: Thermal verification should be integrated into the design process as early as possible. This allows engineers to identify and address thermal issues before the chip reaches the production stage.

- Use of Industry-Standard Equipment: Employing industry-standard thermal forcing systems and temperature control technologies ensures that the results of thermal verification are accurate and reliable.

Challenges in Silicon Thermal Verification

While silicon thermal verification is essential, it is not without its challenges. Engineers often face the following difficulties:

- Miniaturization: As silicon chips become smaller, managing heat dissipation becomes more challenging. Ensuring that these tiny components remain within safe thermal limits requires advanced cooling technologies and precise temperature control.

- Complexity of Modern Chips: Today’s silicon chips are more complex than ever, with multiple layers and components that can generate heat. Thermal verification must account for these complexities to provide accurate assessments.

- Cost and Time Constraints: Thermal verification can be a time-consuming and costly process. Balancing the need for thorough testing with project timelines and budgets is a common challenge for engineers.

The Future of Silicon Thermal Verification

The field of silicon thermal verification is continuously evolving. As semiconductor technology advances, new thermal management challenges will emerge, requiring innovative solutions. Some trends to watch for include:

- AI and Machine Learning in Thermal Management: The integration of AI and machine learning could revolutionize thermal verification by predicting thermal behavior and optimizing cooling strategies in real-time.

- Increased Automation: Automation in thermal testing is expected to improve efficiency, reduce costs, and enhance the accuracy of thermal verification processes.

- Advanced Materials for Cooling: The development of new materials with superior thermal conductivity could lead to more effective cooling solutions, improving the overall reliability of silicon chips.

Conclusion

Silicon Thermal Verification is a critical process in ensuring the reliability and performance of modern semiconductor devices. By leveraging advanced technologies like thermal forcing systems, precision cooling solutions, and temperature control systems, engineers can effectively manage the thermal challenges associated with today’s high-performance silicon chips.

As semiconductor technology continues to advance, the importance of robust thermal verification will only grow. Engineers who stay ahead of the curve by adopting the latest thermal management solutions will be well-positioned to meet the demands of the future.

Explore how advanced thermal management solutions can enhance your silicon verification processes and ensure your designs meet the highest standards of reliability and performance.