Introduction to Thermal Forcing

In the advanced landscape of semiconductor testing, maintaining precise temperature control during silicon verification is crucial. Thermal forcing plays a vital role in this process, offering a reliable way to simulate extreme thermal environments for testing electronic components. This guide will delve into the concept of thermal forcing, its importance in silicon verification, and how innovative solutions like Peltier technology are making strides in the industry.

Understanding Thermal Forcing Systems

What is a Thermal Forcing System?

A thermal forcing system is a specialized setup designed to control the temperature of electronic components during testing. These systems can rapidly change the temperature to simulate the operating conditions a component may face in real-world environments. Whether it’s extreme cold or intense heat, thermal forcing systems ensure that components are tested under precise conditions, validating their performance, reliability, and durability.

Why is Thermal Forcing Important in Silicon Verification?

Silicon verification is the process of testing semiconductor devices to ensure they meet design specifications and performance requirements. During this process, temperature plays a critical role, as semiconductor behavior can significantly change under different thermal conditions. Thermal forcing systems allow engineers to conduct these tests with high accuracy, ensuring that the silicon components will function correctly across a wide range of temperatures.

Peltier Technology: A Key Component in Modern Thermal Forcing

What is Peltier Technology?

Peltier technology, named after the French physicist Jean Charles Athanase Peltier, involves the use of thermoelectric devices that create a heat flux between the junction of two different materials. When an electric current passes through the device, heat is absorbed at one side and dissipated at the other, making it possible to achieve precise temperature control. This technology is highly efficient and is widely used in thermal forcing systems.

How Peltier Technology Enhances Thermal Forcing Systems

Incorporating Peltier technology into thermal forcing systems provides numerous benefits:

- Precision: Peltier devices offer fine temperature control, which is essential for accurate silicon verification.

- Reliability: With fewer moving parts compared to traditional cooling systems, Peltier-based solutions are more reliable and require less maintenance.

- Scalability: These systems can be scaled to meet the needs of different testing environments, making them versatile for various applications.

Thermal Solutions for Silicon Verification

The Importance of Temperature Control in Semiconductor Testing

In the semiconductor industry, ensuring that components can withstand various thermal environments is crucial. Thermal solutions for silicon verification provide a way to simulate these conditions and assess the performance of chips under stress. Effective temperature management during testing can reveal potential issues, such as thermal runaway or failure at extreme temperatures, that could compromise the reliability of the final product.

Sysmetric-TFS: Leading the Way in Thermal Forcing Solutions

At Sysmetric-TFS, we specialize in cutting-edge thermal forcing systems designed to meet the rigorous demands of silicon verification. Our solutions are built with Peltier technology, offering superior precision and reliability. We understand the critical nature of semiconductor testing, and our systems are engineered to provide the highest level of temperature control, ensuring that your components meet the most stringent performance standards.

About Thermal Forcing Systems

Key Features of Thermal Forcing Systems

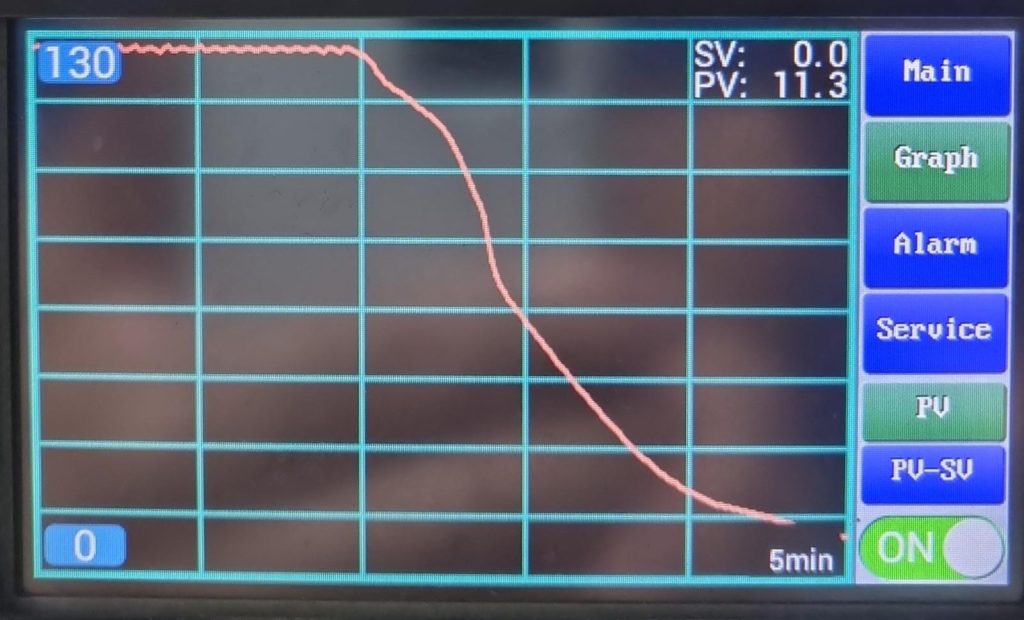

- Rapid Temperature Cycling: Thermal forcing systems can quickly switch between hot and cold temperatures, allowing for thorough testing in a short period.

- Customizable Testing Environments: These systems can be tailored to simulate a wide range of thermal environments, from freezing cold to scorching heat.

- Data Logging and Analysis: Modern thermal forcing systems are equipped with advanced software that logs temperature data and provides detailed analysis, helping engineers make informed decisions.

Applications of Thermal Forcing Systems

Thermal forcing systems are used in various applications, including:

- Semiconductor Manufacturing: Ensuring that chips can operate reliably under different temperatures.

- Aerospace: Testing components that will be exposed to extreme thermal environments in space.

- Automotive: Validating the performance of electronic components in vehicles, where temperature variations can be significant.

Conclusion: The Future of Thermal Forcing

As the demand for reliable semiconductor components continues to grow, so does the need for precise temperature control during testing. Thermal forcing systems are at the forefront of this evolution, providing the tools necessary to ensure that every chip meets the highest standards of performance and reliability. With innovations like Peltier technology leading the way, companies like Sysmetric-TFS are setting new benchmarks in the industry, making sure that every product is tested under the most accurate conditions possible.

For more information on how Sysmetric-TFS can enhance your silicon verification process, visit our website and discover our range of thermal forcing solutions.