Phase-change cooling is an advanced thermal management technique that is gaining popularity for its efficiency in managing heat in high-performance systems, such as those used for silicon verification solutions. This method leverages the latent heat of vaporisation, where a liquid turns into vapour, absorbing heat in the process. This absorbed heat is then dissipated as the vapour condenses back into liquid, creating an ongoing loop of heat transfer with minimal energy loss.

1. How Phase-Change Cooling Works

Phase-change cooling is particularly effective for thermal chamber designs and heat exchanger types. In this system, the cooling fluid absorbs waste heat generated by electrical components, transitions into a gaseous state, and moves to a cooler part of the system. Here, it releases the heat and condenses back into a liquid, ready to repeat the process. This method allows continuous heat transfer without a significant rise in the internal temperature(Phase change systems).

2. Application in Silicon Verification

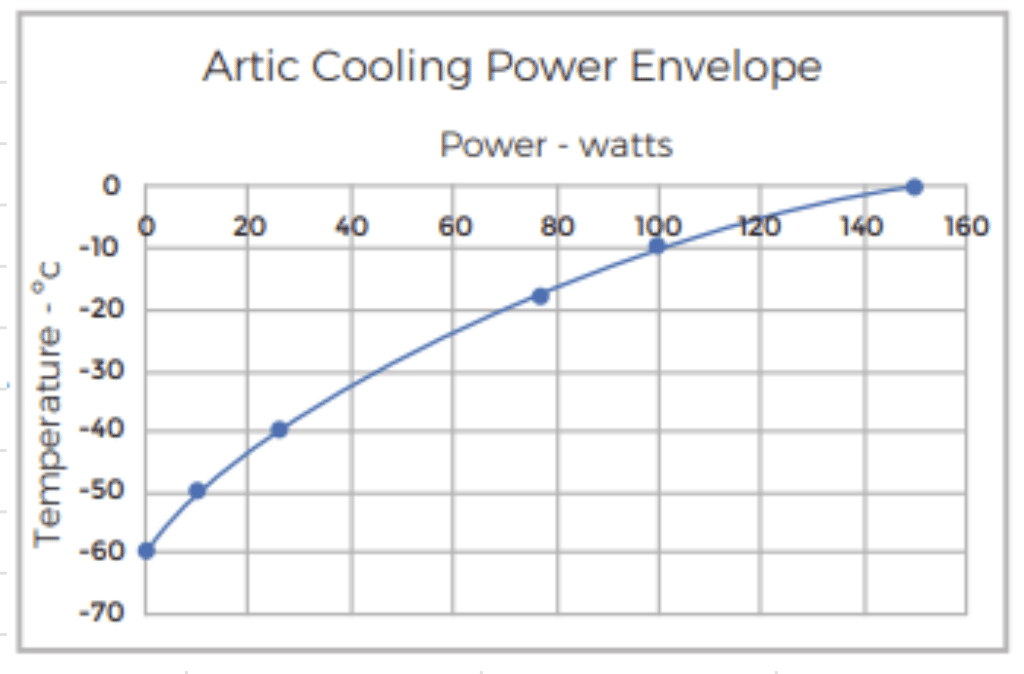

In silicon verification solutions, maintaining temperature stability is critical to ensure that the silicon components meet performance specifications across various thermal conditions. Phase-change cooling is highly effective in such environments, where extreme heat generated by high-power components needs to be dissipated quickly and efficiently. Incorporating peltier junctions or peltier heat pumps in phase-change systems can further enhance cooling precision for specific applications(Electronics Cooling).

3. Heat Exchanger Designs

Phase-change systems often rely on different types of heat exchangers to manage thermal energy. These heat exchangers are designed to ensure efficient heat transfer between the phase-change material (PCM) and the external environment. There are several types, including air-to-air and air-to-water exchangers, which can be customised based on the specific cooling requirements of the system

). These exchangers prevent overheating and ensure that systems operate within safe thermal limits.

4. Exploring Thermal Exchanger Innovations

One emerging trend is the integration of PCMs into thermal exchangers, enhancing their ability to manage fluctuating heat loads in environments with variable external temperatures. The use of paraffin waxes or hydrated salts in heat exchangers allows them to absorb and release heat during peak load conditions, providing a stable operating temperature(Electronics Cooling).

5. Benefits of Phase-Change Cooling

Compared to traditional cooling systems like air conditioning, phase-change cooling offers several advantages:

- Energy Efficiency: Requires less energy as it utilises the natural phase transitions of the cooling fluid.

- Eco-Friendly: Reduces the need for harmful chemicals often used in traditional cooling systems.

- Low Maintenance: Systems are more reliable and require less frequent maintenance than mechanical cooling systems

In conclusion, phase-change cooling represents a sophisticated and effective solution for managing the thermal challenges of modern electronic systems. Whether used in silicon verification or broader thermal management applications, this technology promises enhanced performance, efficiency, and sustainability.