Introduction

In the rapidly evolving field of electronics, where every component is pushed to its performance limits, ensuring reliability is paramount. One critical aspect of this is thermal management, especially during silicon verification processes. As integrated circuits (ICs) become more complex, managing heat effectively becomes essential to maintaining the integrity and functionality of these devices. Advanced Thermal Forcing Cooling Solutions are at the forefront of this challenge, providing precise temperature control that ensures silicon devices perform as expected under various conditions. But why is it crucial to perform thorough checks on these cooling solutions? This article delves into the necessity of such checks, emphasizing their importance in the broader context of silicon verification.

Why Thermal Management is Crucial in Silicon Verification

Thermal management is a vital component of silicon verification, the process by which the functionality of a silicon chip is tested to ensure it meets design specifications. During verification, chips are subjected to various operational conditions, including different temperatures, to assess their performance. Improper thermal management can lead to overheating, which can cause a chip to fail prematurely, lead to inaccurate test results, or even damage the chip permanently.

Effective thermal management ensures that the chip operates within safe temperature limits, providing accurate and reliable test results. It also extends the life of the chip, as prolonged exposure to high temperatures can degrade the materials used in silicon manufacturing, leading to failures in the field. Thus, incorporating advanced thermal solutions into silicon verification is not just about managing heat—it’s about safeguarding the chip’s longevity and ensuring the validity of the entire verification process.

What is Advanced Thermal Forcing Cooling?

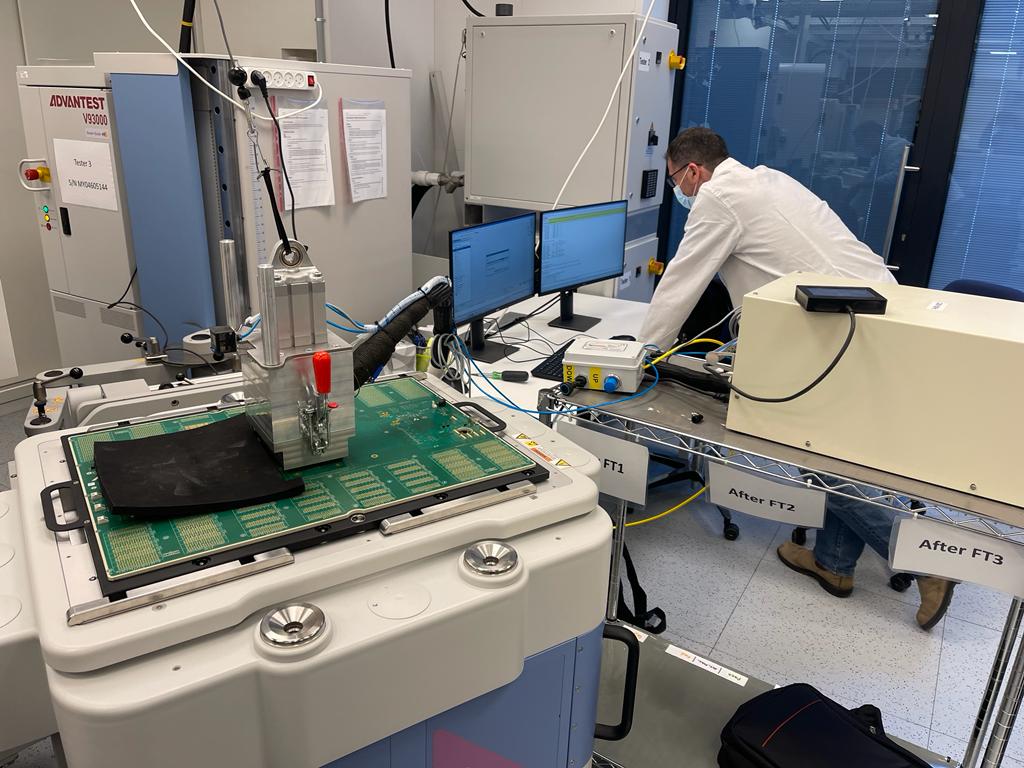

Advanced Thermal Forcing Cooling involves the use of sophisticated systems to precisely control the temperature of a device under test (DUT) during verification. These systems can rapidly heat or cool the DUT to simulate various operating environments. This simulation is crucial in verifying how a silicon chip will perform in real-world conditions, where temperature fluctuations are common.

Unlike traditional cooling methods, advanced thermal forcing systems offer a higher degree of control, allowing for more accurate and consistent testing. They are capable of maintaining very tight temperature tolerances, which is critical when verifying high-performance silicon chips that operate within narrow thermal margins. The precision offered by these systems ensures that any thermal-related issues are identified and addressed before the chip is deployed in the field.

The Necessity of Cooling Solution Checks

Performing regular checks on Advanced Thermal Forcing Cooling Solutions is essential for several reasons:

- Reliability Assurance: Over time, cooling systems can degrade due to wear and tear. Regular checks ensure that these systems continue to operate at their optimal performance levels, providing consistent and reliable thermal management during silicon verification.

- Performance Accuracy: Accurate temperature control is crucial for obtaining valid test results. Even slight deviations in temperature can lead to incorrect conclusions about a chip’s performance. Routine checks help maintain the accuracy of the cooling system, ensuring that the silicon verification process yields dependable data.

- Preventing Overheating: Silicon chips are highly sensitive to temperature. If a cooling solution fails or operates sub-optimally, the chip could overheat, leading to irreversible damage. Regular checks help identify potential issues before they result in costly failures.

- Safety: Faulty cooling systems can pose safety risks, including the potential for fires or equipment damage. Regular inspections reduce these risks by ensuring that all components of the cooling system are functioning correctly.

- Cost Efficiency: Identifying and addressing issues in a cooling system before they cause major problems can save significant costs in terms of both repairs and the potential loss of valuable silicon chips. This preventive approach reduces downtime and avoids the need for expensive emergency fixes.

How to Perform Effective Cooling Solution Checks

To ensure that Advanced Thermal Forcing Cooling Solutions operate effectively, it’s important to follow a structured approach to maintenance and checks:

- Regular Inspections: Establish a routine inspection schedule that includes checking all components of the cooling system, such as fans, compressors, heat exchangers, and sensors. Look for signs of wear and tear, and replace any components that show signs of degradation.

- Calibration: Regularly calibrate temperature sensors and controllers to ensure they provide accurate readings. Calibration should be performed according to the manufacturer’s specifications, using certified reference standards.

- Testing Under Load: Simulate operational conditions by running the cooling system with a DUT in place. Monitor the system’s performance to ensure it can maintain the required temperature range without fluctuations.

- Software Updates: Ensure that the cooling system’s software is up to date. Manufacturers often release updates that improve system performance or address known issues. Keeping the software current ensures that the system benefits from the latest enhancements.

- Documentation: Maintain detailed records of all checks, calibrations, and maintenance activities. This documentation is valuable for tracking the performance of the cooling system over time and for identifying trends that may indicate potential problems.

Impact of Proper Thermal Management on Silicon Verification

Proper thermal management, supported by regular checks of Advanced Thermal Forcing Cooling Solutions, has a profound impact on the silicon verification process. It ensures that chips are tested under realistic conditions, which improves the accuracy of the verification process. This, in turn, reduces the likelihood of field failures, as the chips that pass verification are more likely to meet the performance and reliability expectations set during testing.

Moreover, by preventing overheating and other thermal issues, these checks extend the lifespan of both the silicon chips and the verification equipment, leading to long-term cost savings. In a competitive market where reliability is key, ensuring that thermal management systems are functioning correctly is not just a technical necessity—it’s a strategic advantage.

Conclusion

In the world of silicon verification, where precision and reliability are paramount, the role of Advanced Thermal Forcing Cooling Solutions cannot be overstated. These systems ensure that chips are tested under accurate thermal conditions, which is critical for verifying their performance and reliability. However, to maintain the effectiveness of these systems, regular checks and maintenance are essential. By understanding the necessity of these checks and implementing a rigorous inspection routine, companies can safeguard their silicon verification processes, ensuring that they deliver products that meet the highest standards of quality and reliability.