DTC Cooling

As semiconductor technology continues to advance, effective thermal management becomes increasingly critical for ensuring the performance and reliability of silicon devices. One innovative solution that has gained attention in recent years is Direct-to-Chip (DTC) cooling. This cooling technology offers precise and efficient thermal regulation for high-performance electronics, making it ideal for thermal validation processes in various industries, including semiconductors, data centers, and high-end computing systems. This article explores DTC cooling, why it is a powerful solution for thermal validation, and its role in silicon thermal validation.

What is Direct-to-Chip (DTC) Cooling?

Direct-to-Chip (DTC) cooling is a cutting-edge cooling technology that involves delivering a cooling fluid directly to the surface of a semiconductor chip or processor. Instead of relying on traditional air or fan-based cooling systems, DTC utilizes liquid coolant that flows through microchannels embedded in a cold plate attached to the chip. The coolant absorbs the heat generated by the chip, preventing it from overheating and maintaining optimal performance levels.

The key to DTC cooling is its ability to remove heat directly from the source—the chip itself. This is achieved by utilizing specialized cold plates that fit precisely over the chip, allowing the coolant to pass through while efficiently extracting heat from the hottest areas of the device. This direct contact between the cooling system and the silicon chip enables precise thermal management and efficient heat dissipation, even under extreme operating conditions.

Why DTC Cooling is Ideal for Thermal Validation

Thermal validation is the process of testing semiconductor devices to ensure that they can operate reliably within their specified temperature ranges. Silicon devices, such as microprocessors and memory chips, generate a significant amount of heat during operation, and failure to manage this heat effectively can result in performance degradation, reduced lifespan, or even catastrophic failure.

DTC cooling is an ideal solution for thermal validation in silicon devices for several reasons:

1. Enhanced Heat Dissipation

DTC cooling provides superior heat dissipation compared to traditional air cooling systems. By directly targeting the chip, DTC can remove heat more efficiently, ensuring that the silicon device remains within its optimal operating temperature range. This enhanced heat removal is critical for thermal validation, where precise temperature control is necessary to test the limits of a device’s thermal performance.

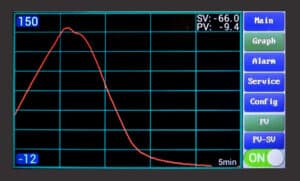

2. Precision Temperature Control

In thermal validation, it is essential to maintain tight temperature control to simulate real-world operating conditions and assess the reliability of silicon devices. DTC cooling systems offer precise temperature control by allowing operators to fine-tune the coolant flow and temperature. This precision ensures that the thermal conditions during validation closely mirror actual operating environments, providing accurate insights into a device’s thermal behavior.

3. Uniform Cooling Across the Chip

One of the main challenges in cooling silicon devices is ensuring uniform temperature distribution across the entire surface of the chip. Uneven cooling can lead to thermal hotspots, which can cause localized damage and negatively affect the overall performance of the device. DTC cooling delivers consistent and uniform cooling across the entire chip, minimizing the risk of hotspots and ensuring reliable thermal validation results.

4. Scalability for High-Performance Applications

As silicon devices become more powerful, the need for effective cooling solutions becomes even more critical. DTC cooling systems are highly scalable and can be adapted for use in high-performance applications, such as data centers, where multiple chips or processors are used simultaneously. This scalability makes DTC cooling an excellent choice for thermal validation in large-scale testing environments, where the ability to cool multiple devices at once is necessary.

5. Energy Efficiency

DTC cooling systems are generally more energy-efficient than traditional air cooling systems, as they can remove heat more effectively without requiring high-speed fans or additional power for heat dissipation. This energy efficiency is particularly important in thermal validation settings, where multiple tests may be conducted over extended periods. Reducing the energy consumption of the cooling system can help lower operational costs and improve the overall sustainability of the validation process.

Silicon Thermal Validation: The Importance of Effective Cooling Solutions

Silicon thermal validation is the process of ensuring that silicon-based semiconductor devices, such as processors and memory chips, can withstand and operate within the required temperature ranges. Given the increasing power density of modern silicon chips, managing the heat they generate is more critical than ever.

During thermal validation, devices are subjected to extreme temperature conditions to evaluate their thermal performance, stability, and reliability. If the cooling system used during validation is not efficient or precise enough, it can lead to inaccurate results or even device failure. This is where DTC cooling shines, offering a high level of control over temperature and ensuring that silicon devices can be properly validated across a range of thermal conditions.

Silicon devices, especially those used in high-performance applications such as data centers, telecommunications, and advanced computing, require meticulous thermal validation to prevent issues such as:

- Thermal Runaway: When a device generates more heat than it can dissipate, causing temperatures to rise uncontrollably.

- Performance Degradation: Excessive heat can slow down processing speeds and reduce the overall efficiency of the silicon device.

- Component Failure: Overheating can cause permanent damage to silicon devices, leading to costly failures or the need for replacement.

DTC cooling helps mitigate these risks by providing a reliable, energy-efficient, and scalable solution for managing heat during the validation process. By ensuring that silicon devices are kept within their safe operating temperature ranges, DTC cooling enables manufacturers to validate the thermal performance of their products with confidence.

Conclusion

Direct-to-Chip (DTC) cooling is a revolutionary solution for managing heat in high-performance semiconductor devices, especially during thermal validation. Its ability to deliver precise, uniform cooling directly to the chip makes it ideal for ensuring the reliability, performance, and longevity of silicon devices. As semiconductor technology continues to evolve and devices become more powerful, DTC cooling will play a critical role in the thermal validation process, helping manufacturers produce high-quality, thermally optimized products.

At Sysmetric-TFS, we specialize in providing state-of-the-art thermal management solutions, including Direct-to-Chip cooling systems, designed to meet the rigorous demands of silicon thermal validation. To learn more about our cutting-edge cooling technologies, visit Sysmetric-TFS.