Semiconductors are the cornerstone of modern electronics, powering everything from smartphones to supercomputers. As these components become smaller and more powerful, managing their thermal performance has become increasingly critical. Semiconductor thermal validation is the process of testing and ensuring that these components can operate within their specified temperature range without degradation or failure. This article explores the importance of thermal validation, the industries and companies that rely on it, and why Peltier-based thermoelectric coolers (TEC) are an optimal solution for conducting these tests.

Why Is Semiconductor Thermal Validation Necessary?

As semiconductor technology advances, the need for precise and reliable thermal management increases. Excess heat in semiconductors can lead to performance degradation, shorter lifespan, and even catastrophic failure. Here are key reasons why thermal validation is essential:

- Performance Optimization: Semiconductors are designed to function optimally within a specific temperature range. If the component overheats, its efficiency decreases, which can impact the overall performance of electronic systems.

- Reliability Assurance: Excessive heat can cause wear and tear on semiconductor materials, leading to long-term reliability issues. Thermal validation ensures that semiconductors will maintain functionality over their expected lifespan.

- Preventing Thermal Runaway: Thermal runaway is a phenomenon where a semiconductor component generates more heat than it can dissipate, leading to a self-sustaining overheating cycle. Validating the thermal properties of semiconductors helps prevent this scenario.

- Quality Control: Semiconductor manufacturers must adhere to strict quality standards. Thermal validation is crucial in verifying that each component meets these requirements before being integrated into larger systems.

- Safety Concerns: Overheating semiconductors can cause dangerous malfunctions in critical applications such as medical devices or aerospace systems. Ensuring proper thermal validation minimizes these risks.

Who Uses Semiconductor Thermal Validation?

Semiconductor thermal validation is a critical process used across multiple industries. It is typically conducted by:

- Semiconductor Manufacturers: Companies that produce microprocessors, memory chips, and other semiconductor devices conduct rigorous thermal testing to ensure their products meet industry standards for reliability and performance.

- Automotive Industry: Modern vehicles rely heavily on semiconductors for various functions, from engine control to autonomous driving features. Ensuring thermal stability in these harsh environments is essential for safe and reliable operation.

- Consumer Electronics: Devices like smartphones, laptops, and gaming consoles generate substantial heat due to their high-performance components. Manufacturers in this space use thermal validation to ensure that their products won’t overheat or degrade over time.

- Aerospace and Defense: Thermal management in aerospace applications is critical due to extreme environmental conditions. The failure of a semiconductor in these settings can lead to mission-critical system failures.

- Medical Device Manufacturers: Medical devices such as imaging systems, diagnostic equipment, and life-support machines all rely on semiconductors. Ensuring these components remain thermally stable is vital for patient safety.

Why Peltier-Based TECs Are the Best Solution for Thermal Validation

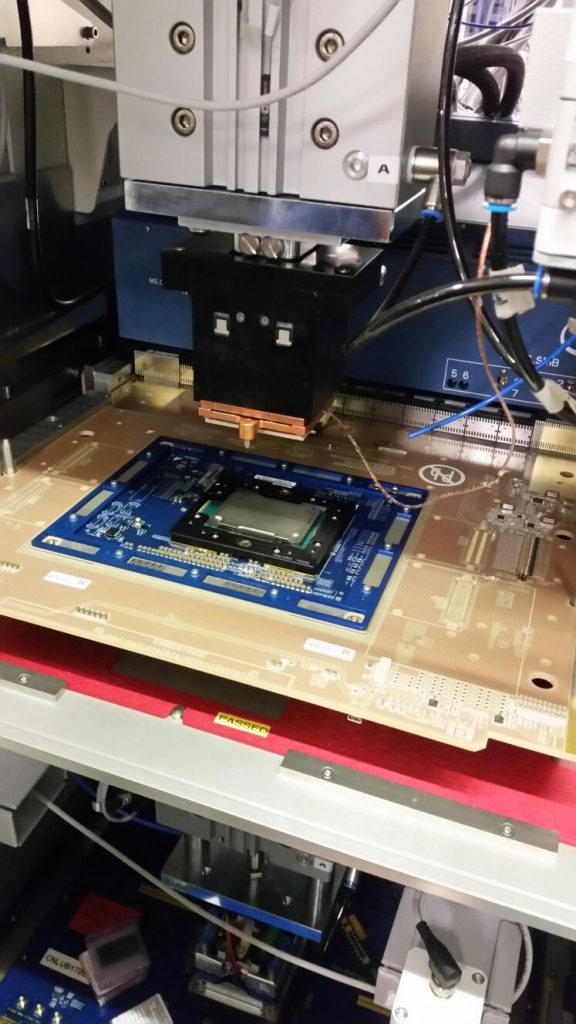

Thermoelectric coolers (TECs) based on the Peltier effect are becoming a popular choice for semiconductor thermal testing. Here are five reasons why they are superior to other cooling solutions:

1. Precision Temperature Control

Peltier-based TECs allow for highly precise temperature control, which is critical for testing semiconductors across a wide range of operating conditions. With the ability to fine-tune temperatures to within fractions of a degree, TECs provide unmatched accuracy for validating semiconductor thermal performance.

2. Fast Response Time

Semiconductor thermal validation often requires rapidly cycling between different temperatures to simulate real-world operating conditions. TECs excel in this regard due to their fast response time. Unlike traditional cooling methods that rely on fans or liquid coolants, TECs can change temperature quickly and efficiently, making them ideal for dynamic testing scenarios.

3. Compact and Scalable

TECs are highly compact, making them suitable for testing small semiconductor components without requiring bulky equipment. This compactness also allows for easy scalability, meaning multiple TECs can be used simultaneously to test larger or more complex semiconductor systems.

4. Environmentally Friendly

TECs operate without the use of refrigerants or other harmful chemicals, which makes them an environmentally friendly option for thermal validation. Their solid-state design ensures that they are both energy-efficient and free from any risk of fluid leaks, a common issue in traditional liquid-based cooling systems.

5. Versatility in Heating and Cooling

One of the most significant advantages of Peltier TECs is their ability to both heat and cool with the same device. This versatility allows for more comprehensive testing, as semiconductors need to be validated across both their minimum and maximum operating temperature ranges. The ability to switch between heating and cooling modes seamlessly makes TECs a versatile tool for thermal validation.

Conclusion

Semiconductor thermal validation is a critical process that ensures the performance, reliability, and safety of components in various industries. As the demand for more efficient and compact electronics grows, the need for precise thermal management will only increase. Peltier-based TECs offer an optimal solution for conducting these tests due to their precision, speed, compactness, and environmental friendliness.

For companies in the semiconductor industry and beyond, integrating TECs into their thermal validation process can lead to better performance outcomes and more reliable products. Sysmetric-TFS specializes in providing cutting-edge solutions for thermal management and testing, including Peltier-based TEC systems, helping companies achieve the highest standards in semiconductor validation.

For more information, visit Sysmetric-TFS and explore our range of thermal testing solutions.