Semiconductor validation and verification encompass a series of processes designed to ensure that semiconductor devices meet specified requirements and function correctly under all intended operating conditions. These processes are critical in identifying design flaws, manufacturing defects, and potential reliability issues before the products reach the market.

Pre-Silicon Validation

Pre-silicon validation refers to the verification activities conducted before the physical fabrication of the semiconductor device. This phase involves using simulation and modeling tools to test the design’s functionality and performance. Techniques such as simulation-based verification and formal verification are employed to detect logical errors and ensure that the design adheres to its specifications. Electronic Design Automation (EDA) tools play a significant role in this phase, facilitating the creation and analysis of complex semiconductor designs. citeturn0search41

Post-Silicon Validation

Once a semiconductor device is fabricated, post-silicon validation takes place. This phase involves testing the actual silicon to verify that it operates as intended in real-world scenarios. Post-silicon validation is crucial for identifying issues that may not have been apparent during pre-silicon testing, such as those arising from process variations or unforeseen interactions between components. Silicon bring-up is a key activity in this phase, involving the initial power-up and testing of the new silicon to ensure basic functionality. citeturn0search0

Functional Verification

Functional verification is the process of ensuring that a semiconductor design behaves according to its specifications. This involves checking that all components of the design interact correctly and perform their intended functions. Verification IP (VIP) and simulation-based verification methods are commonly used to create test scenarios that mimic real-world applications, allowing designers to observe and correct any deviations from expected behavior. citeturn0search24

Hardware Verification

Hardware verification focuses on testing the physical implementation of the semiconductor design. This includes assessing the hardware’s performance, power consumption, and thermal characteristics. Emulation and prototyping are techniques used in this phase to create physical models of the design, enabling comprehensive testing and validation before mass production. citeturn0search9

Testing and Quality Assurance in Semiconductor Manufacturing

Ensuring the quality and reliability of semiconductor devices requires a series of rigorous testing procedures throughout the manufacturing process.

Wafer-Level and Package-Level Testing

Wafer-level testing involves evaluating the electrical performance of individual dies on a semiconductor wafer before they are separated and packaged. This process helps identify defective dies early, improving overall yield and reducing costs. Package-level testing, on the other hand, assesses the functionality of the packaged semiconductor devices to ensure they meet performance standards. citeturn0search18

Reliability Testing and Burn-In Tests

Reliability testing evaluates a device’s ability to perform under various stress conditions over time, aiming to predict its lifespan and identify potential failure modes. Burn-in tests subject devices to elevated temperatures and voltages to accelerate aging and detect early-life failures. These tests are essential for ensuring long-term reliability and performance. citeturn0search2

Automated Test Equipment (ATE) and Yield Analysis

Automated Test Equipment (ATE) is used to perform high-speed testing of semiconductor devices, facilitating efficient and accurate assessment of their functionality. Yield analysis involves examining the data from these tests to identify trends and areas for process improvement, ultimately enhancing manufacturing efficiency and product quality. citeturn0search7

Design Methodologies for Enhanced Testability

Incorporating testability features into semiconductor designs is crucial for efficient testing and quality assurance.

Design for Test (DfT) and Design Rule Checks (DRC)

Design for Test (DfT) involves integrating specific features into a semiconductor design to facilitate easier and more effective testing post-manufacturing. Techniques such as scan chains and Built-In Self-Test (BIST) are examples of DfT methodologies. Design Rule Checks (DRC) are automated verifications that ensure a design complies with the manufacturing process’s geometric and connectivity constraints, preventing issues during fabrication. citeturn0search1

Verification IP (VIP) and EDA Tools

Verification IP consists of pre-verified components used to test specific functionalities within a design, streamlining the verification process. Electronic Design Automation (EDA) tools provide comprehensive solutions for designing, simulating, and verifying semiconductor devices, playing a pivotal role in modern semiconductor development. citeturn0search5

Failure Analysis and Reliability Assessments

Identifying and understanding the causes of semiconductor device failures are essential for improving design and manufacturing processes.

Failure Analysis (FA) and Fault Isolation

Failure Analysis involves the systematic examination of failed devices to determine the root causes of failures. Fault isolation techniques are used to pinpoint specific areas or components within a device that are responsible for malfunctions, facilitating targeted improvements. citeturn0search10

Reliability Qualification and Stress Testing

Reliability qualification assesses whether a device meets predefined reliability standards and is fit for its intended application. Stress testing subjects devices to extreme conditions, such as high temperatures or voltages, to evaluate their robustness and identify potential failure mechanisms. citeturn0search6

Process and Manufacturing Considerations

Ensuring consistency and quality in semiconductor manufacturing requires meticulous process validation and control.

Process Validation and Variation

Process validation confirms that the manufacturing process consistently produces devices meeting predetermined specifications. Managing process variation is critical, as deviations can certainly impact device performance and yield. By tightly monitoring parameters and conducting parametric tests, manufacturers can maintain high standards and reduce the risk of costly failures. (semiengineering.com)

Device Characterization and Wafer Acceptance Test (WAT)

Device characterization involves measuring the electrical properties of semiconductor devices to understand their behavior under different conditions. This process helps refine models and guide design optimizations. The Wafer Acceptance Test (WAT) is a critical step in evaluating wafers before they proceed to packaging, ensuring only high-quality die move forward in production. (techinsights.com)

Yield Optimization

Yield optimization involves analyzing data across the entire manufacturing chain to identify and rectify issues affecting the percentage of functional devices per wafer. Techniques such as statistical process control, advanced analytics, and root cause analysis are key to improving yields and maximizing profitability. (semiengineering.com)

SoC Validation: A Specialized Approach

As modern electronics increasingly rely on complex System-on-Chip (SoC) designs, SoC validation has become a specialized and critical task. SoC validation combines aspects of both software and hardware testing, ensuring that the integrated components function seamlessly together.

This validation must address communication protocols, memory coherence, and power management strategies, requiring advanced simulation tools, emulators, and FPGA-based prototyping. SoC validation ensures not only functional correctness but also performance targets and power efficiency. (semiengineering.com)

The Role of Testing & QA (Quality Assurance)

Quality Assurance (QA) in semiconductors isn’t just a phase—it’s a philosophy that permeates every stage from design through production. Testing & QA strategies ensure that each device delivered to the market has met rigorous functional, electrical, and reliability benchmarks.

Key QA practices include:

- Design Verification Plans to define expected behavior and corner cases.

- Regression Testing to ensure updates do not introduce defects.

- Data Logging and Analytics for continual improvement in production environments.

These measures help semiconductor companies meet compliance standards and customer expectations. (ieee.org)

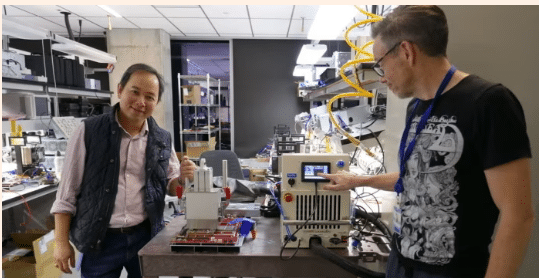

Sysmetric-TFS: Engineering Trust in Every Silicon Layer

Sysmetric-TFS, through its robust approach to semiconductor validation and verification, delivers end-to-end solutions that empower designers and manufacturers to produce reliable, efficient, and high-yield devices. With expertise in post-silicon validation, SoC validation, failure analysis, and advanced testing methodologies, Sysmetric-TFS offers the tools and services that transform complex challenges into scalable innovations.

Explore Sysmetric-TFS’s full suite of services and discover how they enable precision and performance from wafer to final test: Visit Sysmetric-TFS

Summary

This article provides a detailed walkthrough of the key stages and terminologies in semiconductor validation and verification. From design rule checks and simulation-based verification to post-silicon validation and automated testing, every phase is essential to ensure high-functioning, reliable semiconductors.